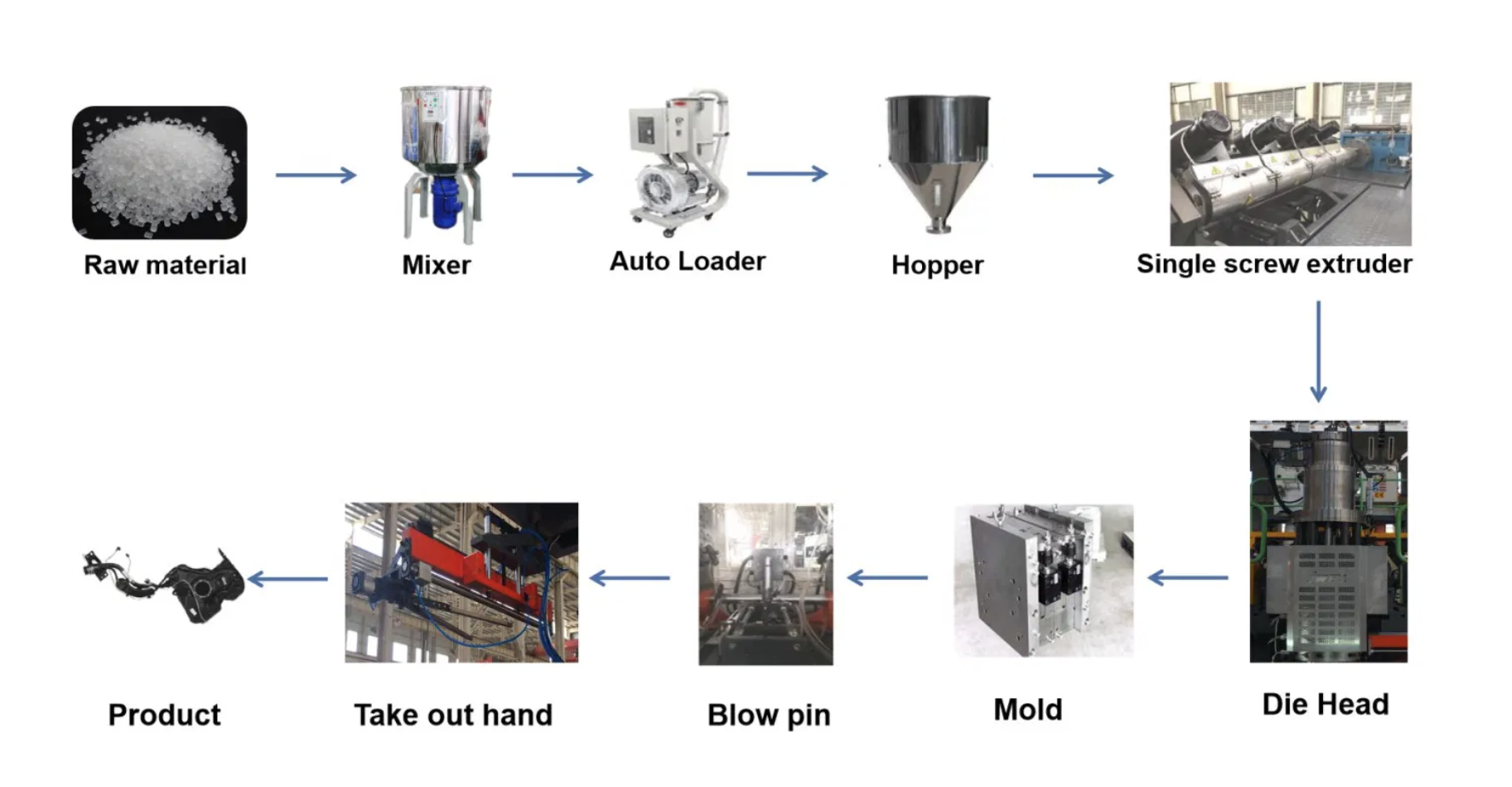

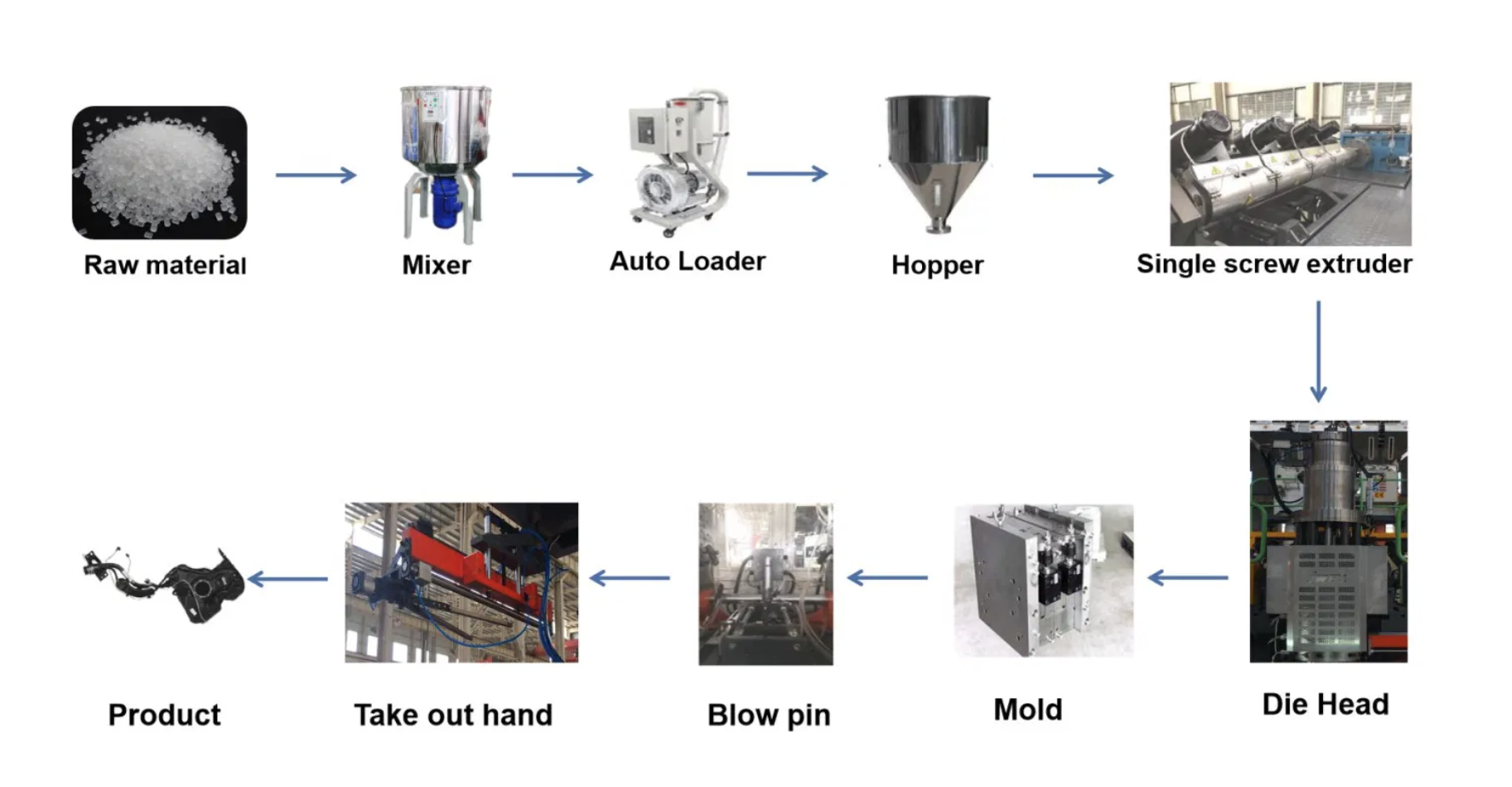

Process Flow

Performance and advantage

Suitable for producing diffferent car shaped pipe fifittings products like the automotive oil fifiller pipe,air ducts pipe and others.

Finished product less or without scrap for strong strength.

Adopt high output extrusion system, accumulating die head.

Optional action elements such as upper encapsulation, product ejection, and core pulling.

Template size can be customized according to product size.

Hydraulic servo control system.

Key Features

Versatility: Designed to produce various irregular pipe products, catering to automotive intake pipes, oil injection tubes, and more.

Flash Reduction: Ensures minimal or no flash during the molding process, enhancing the strength and quality of the products.

High-Yield Extrusion System: Facilitates increased productivity, enabling efficient production of high-quality products.

Material Storage Type Die Head: Optimizes material flow and distribution, ensuring precise and consistent molding.

Advanced Technology: Incorporates advanced features for improved performance and reliability, meeting the demands of modern manufacturing processes.

Applications

Technical parameters

Model | Unit | JWZ-BM 3D-100(take out robot) | JWZ-BM-100 3D(vacuum suction) |

Main screw diameter | mm | 65 | 80 |

Screw L/D | ---- | 25:1 | 25:1 |

Screw rpm | r/min | 25-75 | 25-75 |

Max plasticizing capacity(PE) | Kg/h | 65-75 | 100-120 |

Platen size W*H | mm | 800*1200 | 1020*1500 |

Mould thickness | mm | 450 | 600 |

Clamping force | KN | 75 | 280 |

Dry Cycle | s | 20 | 10 |

Platen moving stroke | mm | 1800 | 360 |

Why Choose Jwell's Blow Molding Machines?

The JWZ-BMQC Series 3D Blow Molding Machine is a versatile solution tailored for the production of various irregular pipe products, including automotive intake pipes and oil injection tubes. This state-of-the-art machine is engineered to ensure minimal or no flash during the molding process, thereby enhancing the strength and quality of the products. Equipped with a high-yield extrusion system and a material storage type die head, it guarantees increased productivity while maintaining precision and consistency. With its advanced features, the 3D Blow Molding Machine is the ideal choice to meet your manufacturing needs.

Purchase Information

For pricing details and further information, please contact our sales team. We offer customized solutions tailored to your specific requirements, backed by superior service and support.