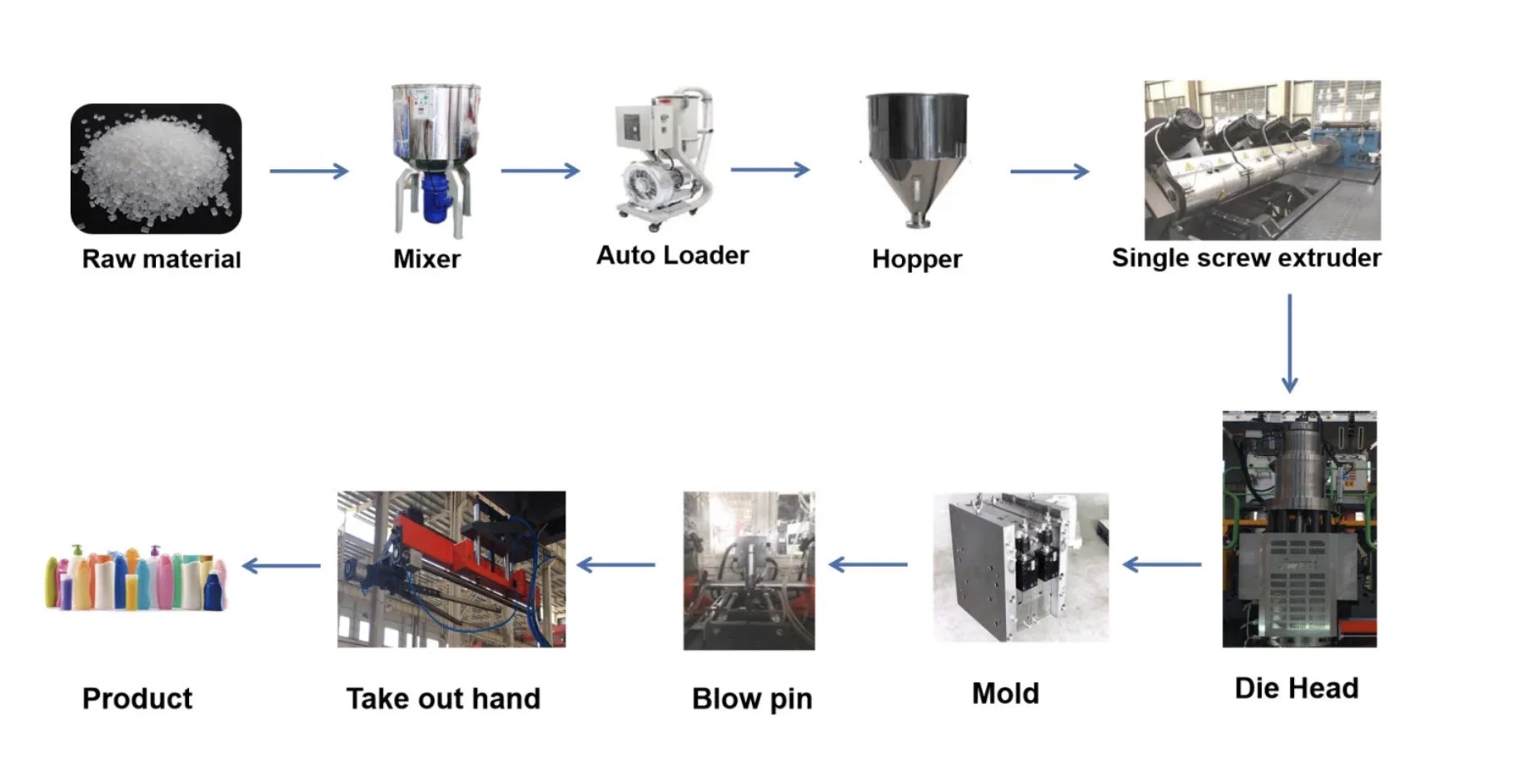

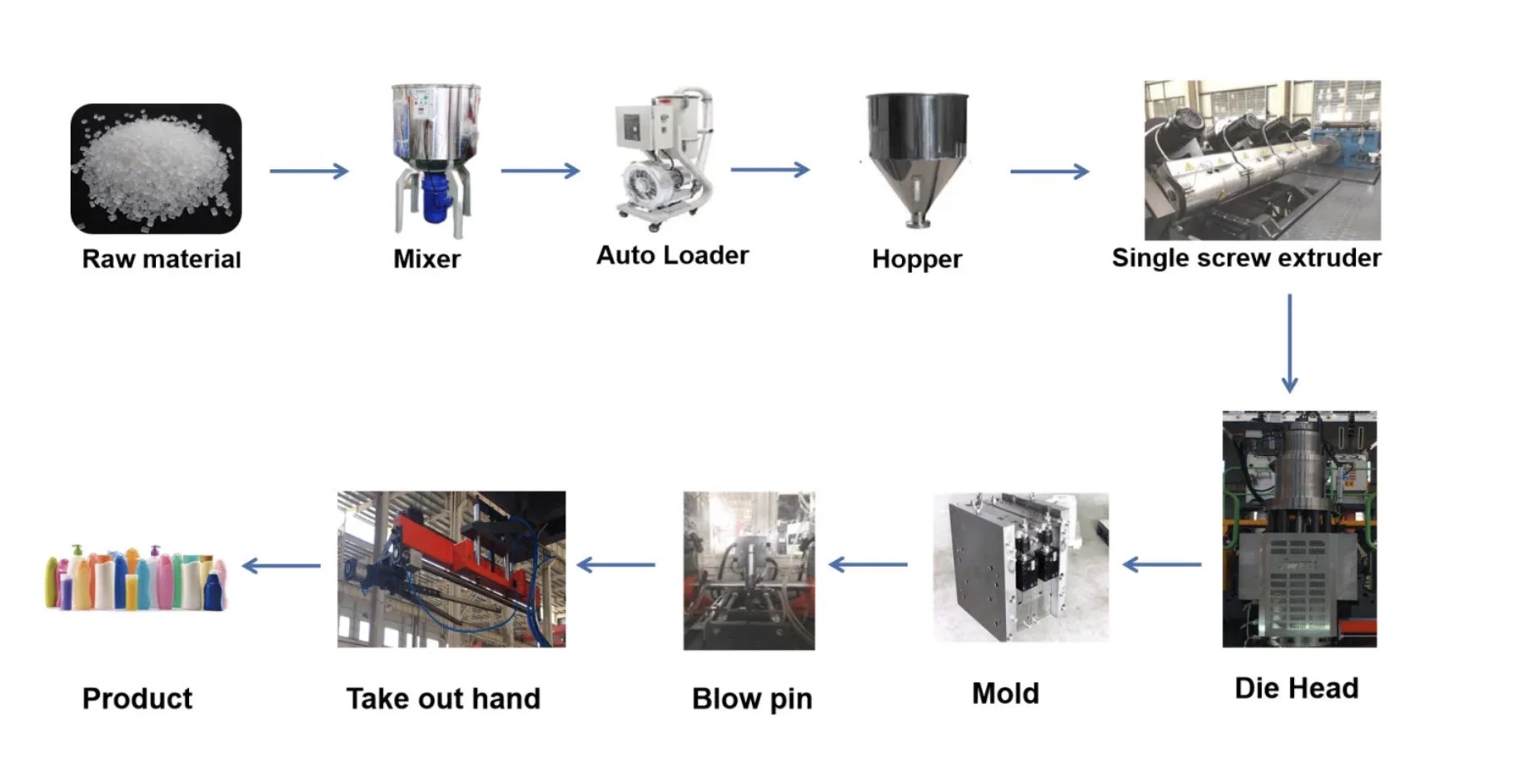

Process Flow

Performance and advantages

·Suitable for producing 1-5L different size of gear oil bottle, lubrication oil bottle, cooling water tank etc.

·Optional multi-layer co-extrusion.

·Optional view strip line system.

·According to the product size,select different cavity of die head.

·According to the different material,optional JW-DB single station hydraulic screen-exchanger system.

·According to customer's requirement,optional auto-deflashing on line,scrap conveying on line,finished product conveying on line.

Applications

Automotive Manufacturing: Ideal for automotive manufacturing facilities seeking efficient production solutions for cooling water tanks.

OEM Suppliers: Perfect for OEM suppliers aiming to produce high-quality automotive components.

Customization Workshops: Suitable for customization workshops catering to clients with specific cooling water tank requirements.

1-5L different size of gear oil bottle, lubrication oil bottle, cooling water tank:our production line is used to produce containers of 1-5L for automotive supplies such as gerar oil bottle,lubrication oil bottle and cooling water tank.

Technical Parameters

Model | Unit | BM05D | BM12D | BM20D |

Max product volume | L | 5 | 12 | 20 |

Dry cycle | Pc/h | 700*2 | 600*2 | 600*2 |

Die head structure | Continuous type |

Main screw diameter | mm | 75 | 90 | 90 |

Max plasticizing capacity(PE) | Kg/h | 90 | 160 | 160 |

Driving motor | Kw | 30 | 45 | 45 |

Oil pump motor power(Servo) | Kw | 15 | 18.5 | 18.5 |

Clamping force | KN | 70 | 120 | 160 |

Space between platen | mm | 150-510 | 240-640 | 280-680 |

Platen size W*H | mm | 420*390 | 520*490 | 500*520 |

Max mould size | mm | 420*400 | 540*500 | 560*520 |

Platen moving stroke | mm | 450/520 | 600/650 | 650 |

Heating power of die head | Kw | 7.5 | 10 | 12.5 |

Machine dimension L*W*H | m | 3.7*3.1*2.7 | 4.2*3.2*3.0 | 4.3*3.2*3.1 |

Machine weight | T | 8.5 | 12 | 14 |

Total power | Kw | 60 | 90 | 93 |

Why Choose Jwell's Blow Molding Machines?

JWZ-BM05D/12D/20D double station blow-molding machine is suitable for large-scale production of 1-5L different size of gear oil bottle, lubrication oil bottle, cooling water tank etc.

We equip with post-cooling device in order to improve the efficiency and shorten the time for bottle forming, so the quality has been guaranteed. In order to meet different demands of the customer, all the dieheads are designed by modern theree dimensional designing softwares ,we also can equip with other downstream equipment, so that auto-deflashing ,conveying and packaging can be achieved.

Purchase Information

For pricing details and further information, please contact our sales team. We offer customized solutions tailored to your specific requirements, backed by superior service and support.