A super mirror roller is a specialized roller used in industrial processes to create highly polished, mirror-like surfaces on materials. Here’s a brief introduction:

1. Function: Super mirror rollers are used to impart a high-gloss, reflective finish to materials such as plastic films, metal foils, and paper.

2. Design:

- Highly Polished Surface: The roller’s surface is polished to a mirror-like finish, typically achieving a surface roughness of Ra 0.01 µm or better.

- Precision Engineering: Made with precise tolerances to ensure consistent and uniform contact with the material.

3. Material: Typically constructed from high-quality stainless steel or other durable metals, often with additional coatings or treatments to enhance hardness and wear resistance.

4.Advantage

1、The surface roughness level of the roller can be reached Ra0.005-0.01μm;

2、Temperature difference accuracy ≤±1℃

3、Hydrogen removal process

4、High-quality 45# seamless pipe, 42CrMo alloy steel forging pipe, Q345D, etc.

6、Enhanced roller rigidity and minimized roller surface temperature deviation through special roller structure design

5. Applications:

- **Plastic Film Manufacturing**: Used to produce high-gloss films for packaging and decorative purposes.

- **Metal Foil Processing**: Applied in the production of reflective metal foils used in electronics and decorative applications.

- **Paper Coating**: Utilized in the production of high-gloss, coated paper for printing and packaging.

Technical Parameters

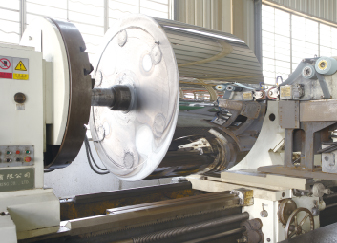

Our manufacturing capacity of roller

Max.machining length:14000mm

Max.machining diameter: ∅1600mm

Max.running speed :800 m/min

Manufacturing precision of roller:

Properalignment :≤0.005mm;

Cylindricity :≤0.005mm;

Surface roughness:Ra0.005-0.01μm

Dynamic balance correction and Static balance correction : G2.5

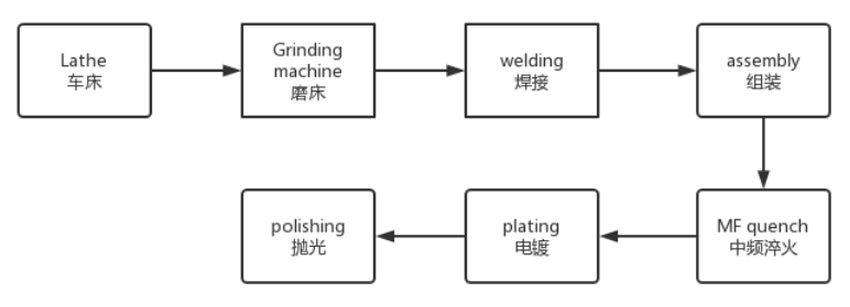

Brief Process Flow Chart