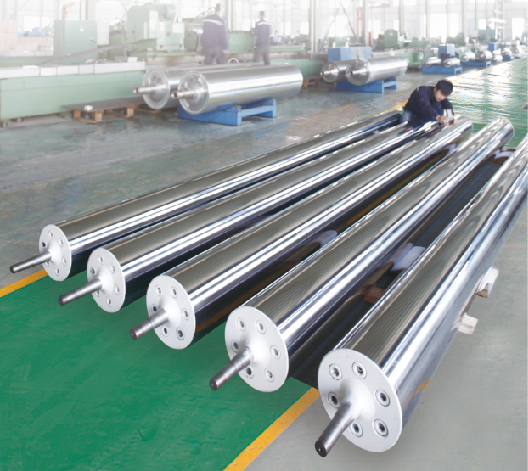

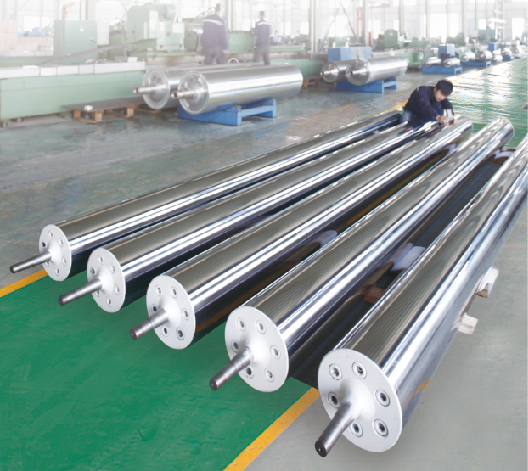

Roller for Bi-Oriented Stretch Film Production Line :

1. Function*: These rollers are used in the production of bi-oriented stretch films, helping to stretch the film biaxially (in both machine and transverse directions) to enhance its strength, clarity, and barrier properties.

2. Design:

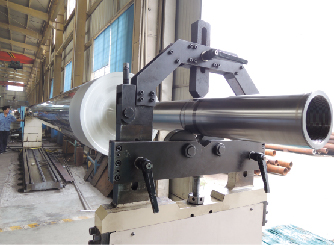

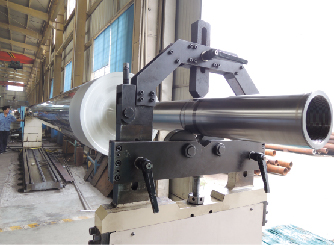

- Precision Engineering: Designed for precise control of film stretching to ensure uniform thickness and consistent film properties.

- Surface Finish: Highly polished surface to prevent sticking and ensure smooth film movement.

- Temperature Control**: Often equipped with heating or cooling systems to manage the film's temperature during the stretching process.

3. **Material: Constructed from high-quality, wear-resistant materials such as hardened steel or chrome-plated steel to withstand the stresses of stretching operations.

4. Advantages:

- Enhanced Film Properties: Improves the mechanical strength, clarity, and barrier properties of the stretch film.

- Uniform Thickness: Ensures consistent film thickness and quality.

- Durability: Built to endure high stress and temperature variations during the stretching process.

5. Applications:

- Packaging Industry: Used to produce high-quality bi-oriented films for food packaging, shrink wraps, and other packaging applications.

- Industrial Uses: Produces films for protective covers, labeling, and other industrial applications requiring durable and strong films.

Our manufacturing capacity of roller:

Maxmachininglength:14000mm

Maxmachining diameter; 1600 mm

Manufacturing precision of roller:

Concentricity: 0.01mm

Cylindricity: 0.01mm

Surface roughness: Ra0.005 - 0.01m

Roller surface treatment:

Electroplate hard chrome coating

Rubber overlay coating

Stainless steel overlay coating

Special coating like TEFLON etc

Due to the higher request for the tension / coated angle/ high line speed/ temperature precision control of thestretching film roller , we can provide the following certificates for each roller:

Shafts material

Outer jacket material

Dimension and geometrical report

Roughness (measures on the sides and in the center of the table)

Chrome coating hardness

Coating thickness (measures on the sides and in the center of the table)

Final balancing reach to G2.5 (machine Printed)

Weight, inertia , d flection under own weight, critical speed

Static pressure test to prevent the leakage

Temperature difference on the table surface

Cooling water flow

lnlet/Outlet water pressure difference